Carl Dumke, Master Collector / Historian

March 1, 2023 by Bill Carter

Filed under Master Horner Profiles

Introducing Carl Dumke, Master Collector / Historian

To date only three Guild members have attained the status of Master Collector / Historian in over 25 years of the Guild’s existence. Carl Dumke

achieved this status on March 5, 2022 which was the culmination of his collecting original horn

items over many years.

Please click here for the entire article as presented in The Horn Book.

Jay Hopkins, Master Collector / Historian

March 1, 2023 by Bill Carter

Filed under Master Horner Profiles

Introducing Jay Hopkins, Master Collector / Historian

There have been only three Guild members who have attained the status of Master Collector / Historian in over 25 years of the Guild’s existence. Dr.Jay Hopkins achieved this status on March 5, 2022 which was the culmination of his collecting powder horns and antique firearms over several decades.

Please click here for the entire article as presented in The Horn Book.

Glenn Beall, Master Collector / Historian

March 1, 2023 by Bill Carter

Filed under Master Horner Profiles

Introducing Glenn Beall, Master Collector / Historian

This is the first article on a member of the Honourable Company of Horners who has achieved the status of Master Collector / Historian.

Please click here for the entire article as presented in The Horn Book.

Clinton Byers, Master Horner

April 22, 2021 by Bill Carter

Filed under Master Horner Profiles

This is the fifteenth installment in a series of articles on those members of the Honourable Company of Horners who have achieved the status of Master Horner.

Here is an excerpt from the Horn Book article on Clinton:

“Clinton Byers is, without question, a welcomed addition to the Masters. It’s always interesting to look into the backgrounds of each Master to learn of their motivation in reaching this level of artisanship.

[To read the complete article, click here…]

Rick Sheets, Master Horner

April 22, 2021 by Bill Carter

Filed under Master Horner Profiles

This is the fourteenth installment in a series of articles on those members of the Honourable Company of Horners who have achieved the status of Master Horner.

Here is an excerpt from the Horn Book article on Rick:

“Rick Sheets brings to the ranks of the Masters an intense interest in educating the public of all ages about the multiple aspects of horn work. ”

and his abundance of patience.

[To read the complete article, click here…]

Walt Mabry, Master Horner

August 18, 2018 by Bill Carter

Filed under Master Horner Profiles

This is the eleventh installment in a series of articles on those members of the Honourable Company of Horners who have achieved the status of Master Horner.

Here is an excerpt from the Horn Book article on Walt:

“He hails from the small town of Golden Meadow, Louisiana, later moving to the New Orleans area where he received his formal school education. Following graduation from high school, Walt attended the University of Southern Mississippi, majoring in Architectural Design with minors in Mathematics and Art.”

[To read the complete article, click here…]

Ed Long, Master Horner

August 18, 2018 by Bill Carter

Filed under Master Horner Profiles

This is the eleventh installment in a series of articles on those members of the Honourable Company of Horners who have achieved the status of Master Horner.

Here is an excerpt from the Horn Book article on Ed:

“Master Horner Ed Long’s path is certainly one of interest, one which saw him attain two of the highest goals possible in the Guild – Guildmaster and Master Horner. Only eight other Guild members have achieved this level of leadership and craftsmanship, an enviable accomplishment indeed!”

[To read the complete article, click here…]

John DeWald, Master Horner

January 3, 2017 by Bill Carter

Filed under Master Horner Profiles

This is the tenth installment in a series of articles on those members of the Honourable Company of Horners who have achieved the status of Master Horner.

Here is an excerpt from the Horn Book article on John:

“John credits his father for his interest in muzzleloading, and ultimately horn work. He introduced John to black powder shooting and “rendezvous” events about 40 years ago.”

[To read the complete article, click here…]

Carl Dumke, Master Horner

August 1, 2014 by Bill Carter

Filed under Master Horner Profiles

This is the ninth in a series of articles on those members of the Honourable Company of Horners who have achieved the status of Master Horner.

Here is an excerpt from the Horn Book article on Carl:

“Carl Dumke’s road to becoming a Master Horner has been unlike any others who have previously traveled down this path. At best, it is a difficult and arduous journey as substantiated by the fact that it has been five years since any Guild member has advanced to the level of Master Horner.”

[To read the complete article, click here…]

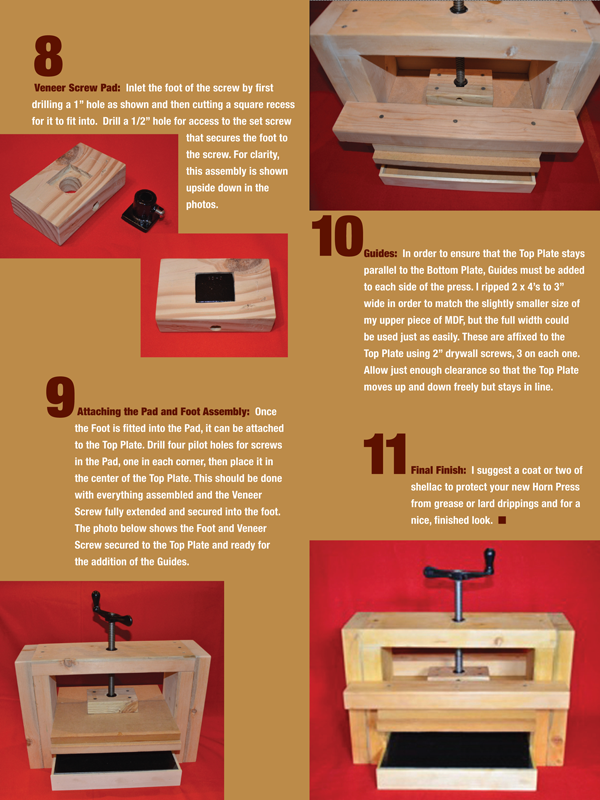

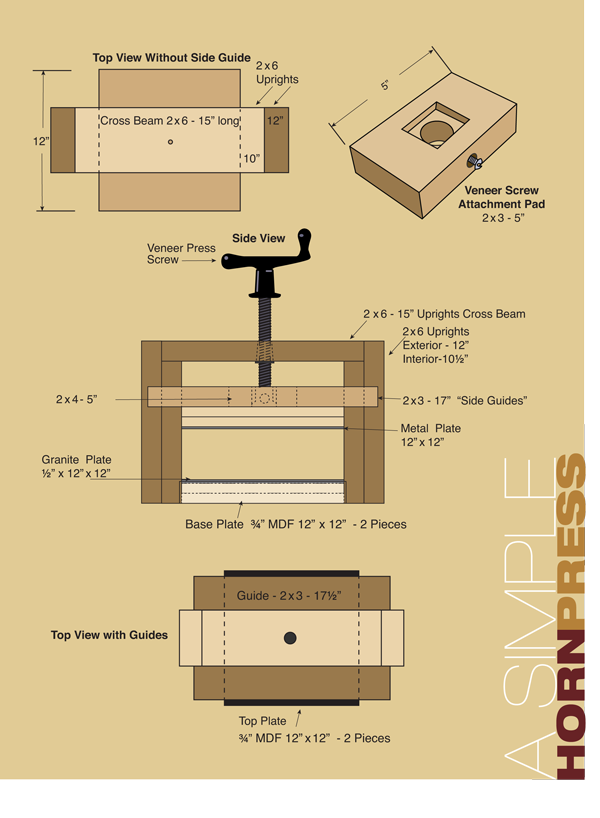

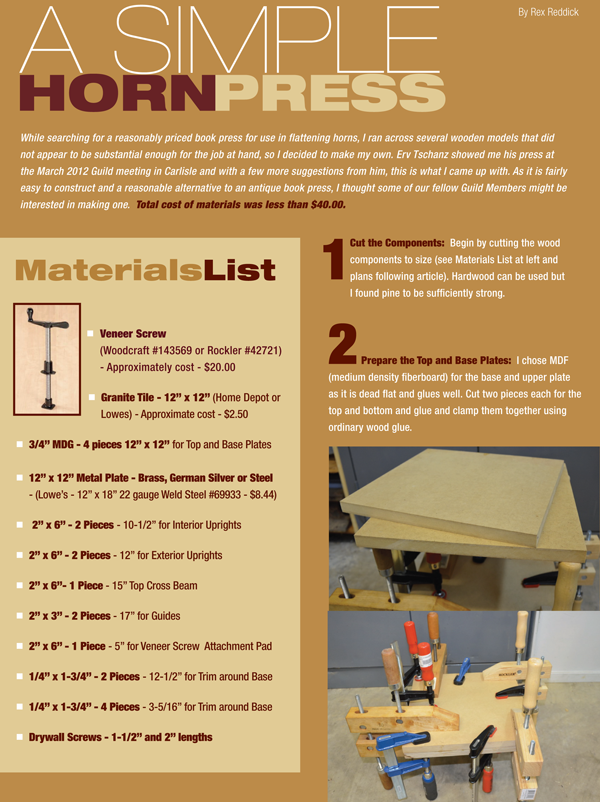

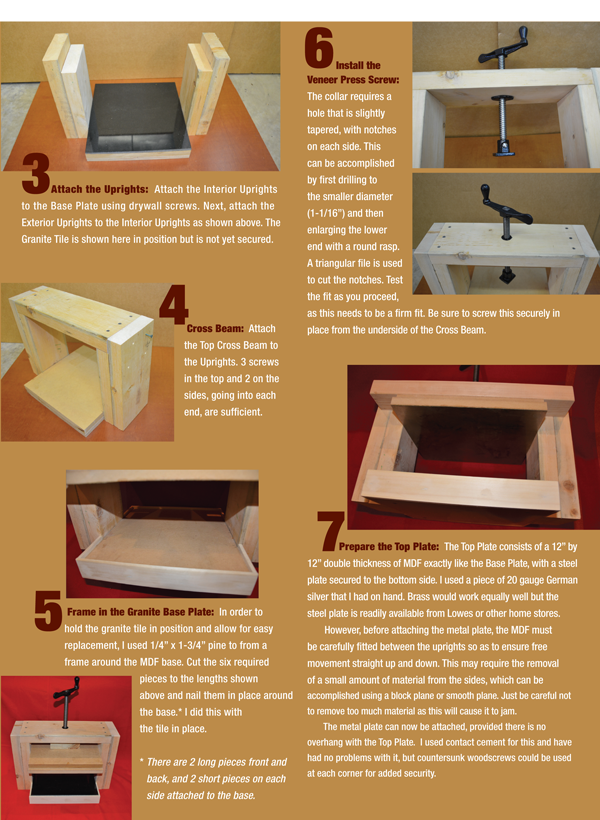

A Simple Horn Press by Rex Reddick

February 12, 2014 by Bill Carter

Filed under Articles from the Archives

This is a reprint from the Summer 2-13 issue of The Horn Book– A Simple Horn Press by Rex Reddick. While it may not be an oldie, it certainly is a goodie! -wec